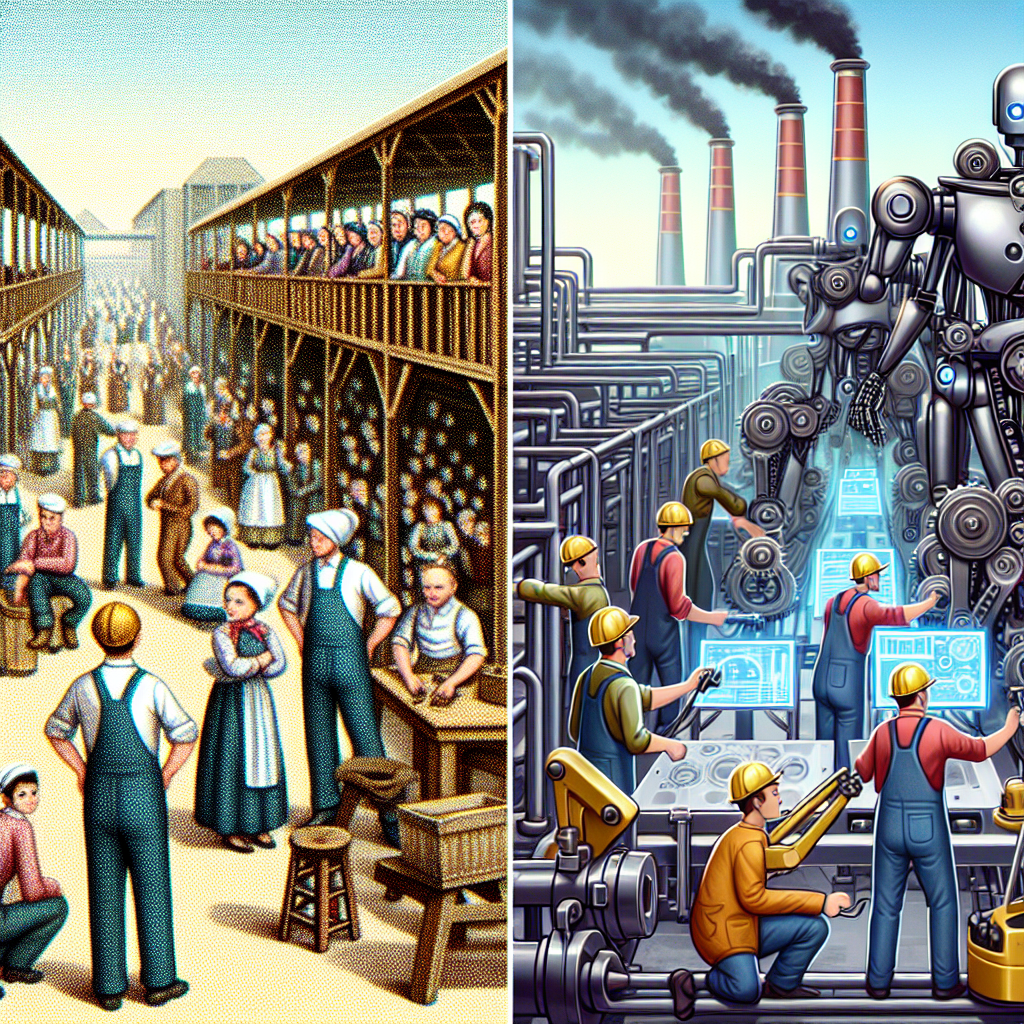

AI Transforming Traditional Manufacturing Industries

In 1961, Unimate rolled off the General Motors assembly line as the first industrial robot. At the time, it was a mechanical marvel—a programmable arm able to perform repetitive tasks without fatigue. Fast forward to today, and that early spark has ignited an industrial revolution. With the integration of artificial intelligence, traditional manufacturing industries are witnessing an unprecedented transformation, redefining how products are designed, manufactured, and delivered.

Revolutionizing the Manufacturing Floor with Smart Automation

AI in manufacturing goes far beyond robotic arms. Unlike simple automation, AI systems can learn from data, adapt to changes, and make decisions in real time. These intelligent capabilities are dramatically improving efficiency and innovation across the manufacturing sector.

Companies leveraging AI technologies experience measurable improvements in operations through:

- Predictive Maintenance: AI-powered sensors monitor equipment in real time, predicting failures before they occur. This reduces costly downtime and extends machine life.

- Quality Control: Computer vision and machine learning models detect defects with higher accuracy than humans, ensuring consistent product quality.

- Inventory Management: AI algorithms forecast demand and optimize stock levels, helping companies reduce waste and storage costs.

Empowering Humans, Not Replacing Them

One of the most common concerns is that AI will replace human jobs. However, in practice, AI is more likely to augment human capabilities than eliminate them. Collaborative robots (cobots) assist workers by handling dangerous or repetitive tasks, allowing employees to focus on higher-level responsibilities such as innovation and strategy. By integrating intelligent systems into workflows, traditional manufacturing companies are upskilling their workforce and improving productivity across the board.

Case Studies: AI in Action

Leading manufacturers are already showing what this transformation looks like:

- BMW: Uses AI-driven analytics to manage its supply chain and production planning, significantly reducing lead times and enhancing flexibility.

- Siemens: Implements AI in its electronics manufacturing plants to optimize energy consumption and streamline product testing processes.

Challenges of Adopting AI in Traditional Manufacturing

Despite the promise, integrating AI into established manufacturing systems is not without challenges:

- Legacy Equipment: Older machinery often lacks the sensors required for data collection.

- Data Silos: AI thrives on data, but many traditional manufacturers have data stored in fragmented or incompatible systems.

- Skilled Talent Shortage: There is a pressing need for AI-literate engineers and data scientists to bridge the implementation gap.

Future Outlook: Smart Manufacturing on the Rise

As AI technologies continue to evolve, traditional manufacturing industries are positioned to become more agile, efficient, and resilient. Businesses that embrace AI will lead the next wave of industrial innovation—reducing costs, boosting production capabilities, and creating safer workplaces in the process.

For manufacturers eager to begin this journey, identifying scalable AI opportunities and partnering with experienced technology providers is essential. Platforms such as McKinsey’s AI in manufacturing insights offer comprehensive guidance for modernizing production without starting from scratch.

Conclusion

AI transforming traditional manufacturing industries is not just a technological trend—it’s the dawn of a new industrial era. By weaving intelligence into the very fabric of manufacturing, companies can unlock new value, remain competitive, and shape the future of global industry.